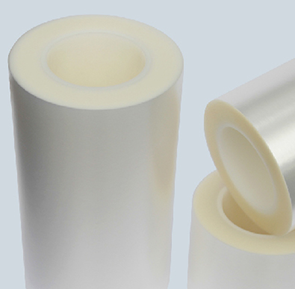

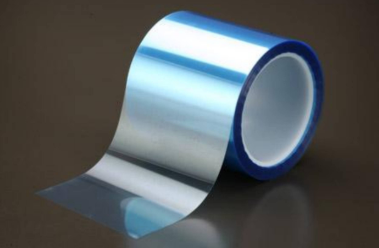

Release films / Fluorocarbon release films

UV-reduced adhesive film with PET as the base material, solvent-free UV curing technology, coated with UV-curable pressure-sensitive adhesive, for the protection of various product processing processes.

keyword:

Category:

Release Film Series

Product Description

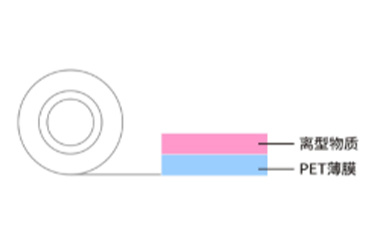

PET is used as the base material and the surface is coated with silicon release material/fluorine release material. The products are widely used in industries such as die-cutting and adhesive products, electronic and electrical appliance manufacturing and other industrial sectors.

|

|

Product Features:

- High cleanliness and no rainbow pattern, processed in a class 10,000 purification environment

- The material is colourful and resistant to organic solvents and does not lose colour when wiped on the surface;

- Small change in peel force over time, easy to peel with long-term use;

- High residual adhesion rate (>90%), very little silicon migration, no influence on the performance of the laminated material, no pollution;

- Good mechanical and weathering properties, effectively ensuring the use in harsh environmental conditions;

Product Applications:

Suitable for industries such as die-cutting industry, adhesive products industry, pressing and demoulding, electronic and electrical appliance manufacturing and other industrial fields.

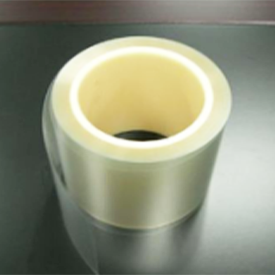

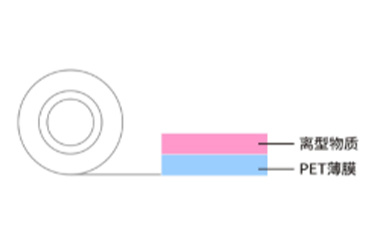

MLCC Release Film Series

|

|

Product Features:

-Processed in a class 10,000 purified environment, with high cleanliness and no rainbow pattern;

-Low variation in peel force over time, easy to peel for long term use;

-High residual adhesion rate (>90%), very little silicon migration, no influence on the performance of the laminated material, no pollution;

-Good mechanical and weathering properties, effectively ensuring the use in harsh environmental conditions;

Product Applications:

Made of optical grade PET substrate with Hard coating treatment on one and both sides. With excellent light transmission and outstanding surface hardness, it is widely used in electronic touch screens, IMD in-moulding, MLCC industry, etc.

Previous

Next

Related Products

Online Message

If you have any suggestions or feedback on our company, please fill in the relevant information on this page and submit it. The staff will contact you in time, or please call us directly.